FOR A CUSTOM QUOTE

STAINLESS STEEL UID PLATES RESIST CORROSION

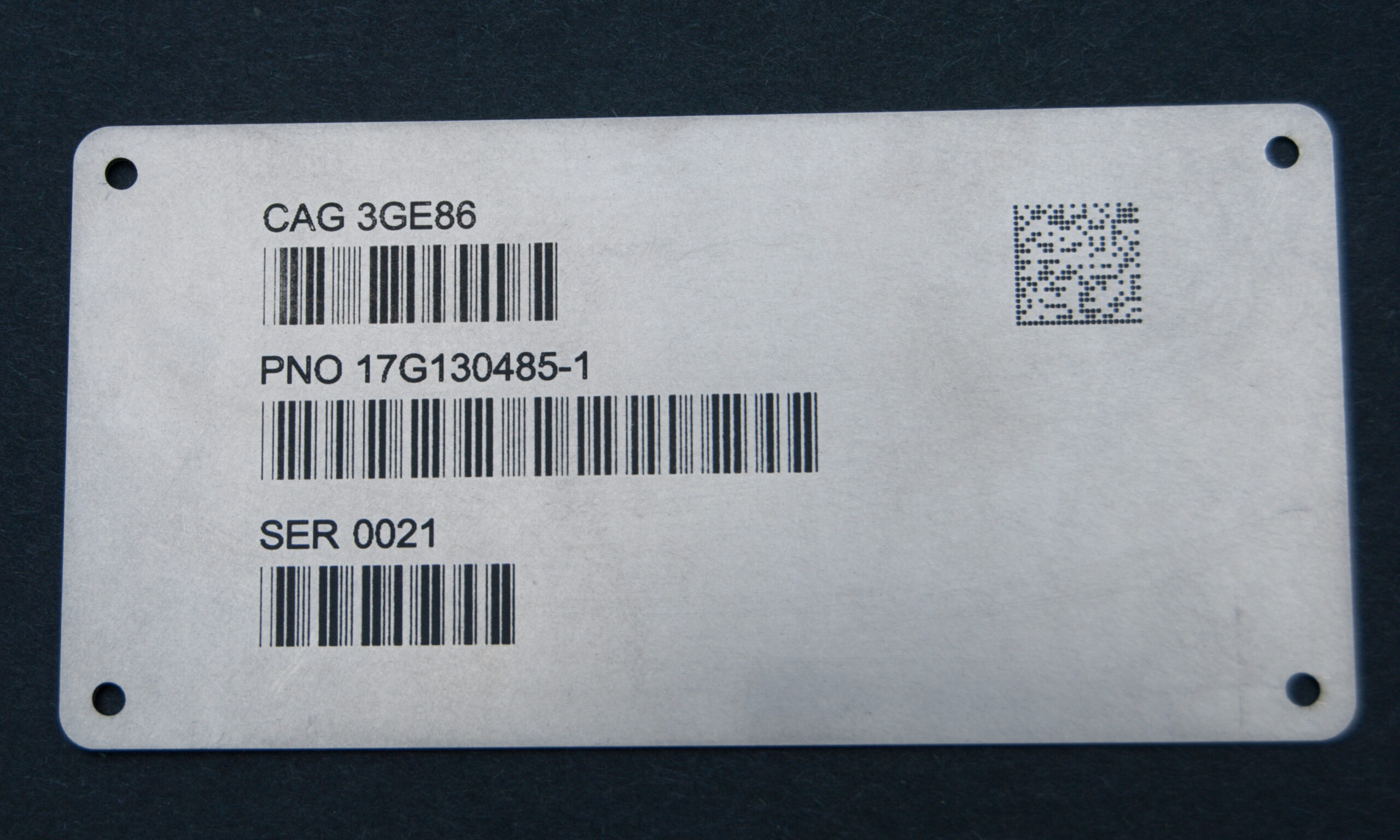

EXPEDITER™ Stainless Steel UID plates offer superior corrosion resistance because our Type 316 Stainless Steel outperforms standard Type 304. Text and barcode markings are as durable as the metal because we laser- fuse Ferro Corporation’s CerMark™ glass-ceramic enamel directly to the Stainless Steel.

Stainless Steel with CerMark™

| Performance | Extra Heavy Duty |

| Marking Method | Cermark™ |

| Distinguishing Feature(s) | Corrosion Resistance |

| Exterior Exposure | > 20 years |

| High Temperature | 750° F |

| Conforms to Curves | No |

| “Peel & Stick” | No |

| Mechanical Fasteners | Yes |

| Resistant to | |

| – Abrasion | Extreme |

| – Acids and Bases | Extreme |

| – Oils, Fuels, Solvents | Extreme |

| – Salt Spray | Extreme |

| – Direct Impact | Yes |