A. We ask how you serialize to find the best DATA CONSTRUCT for you

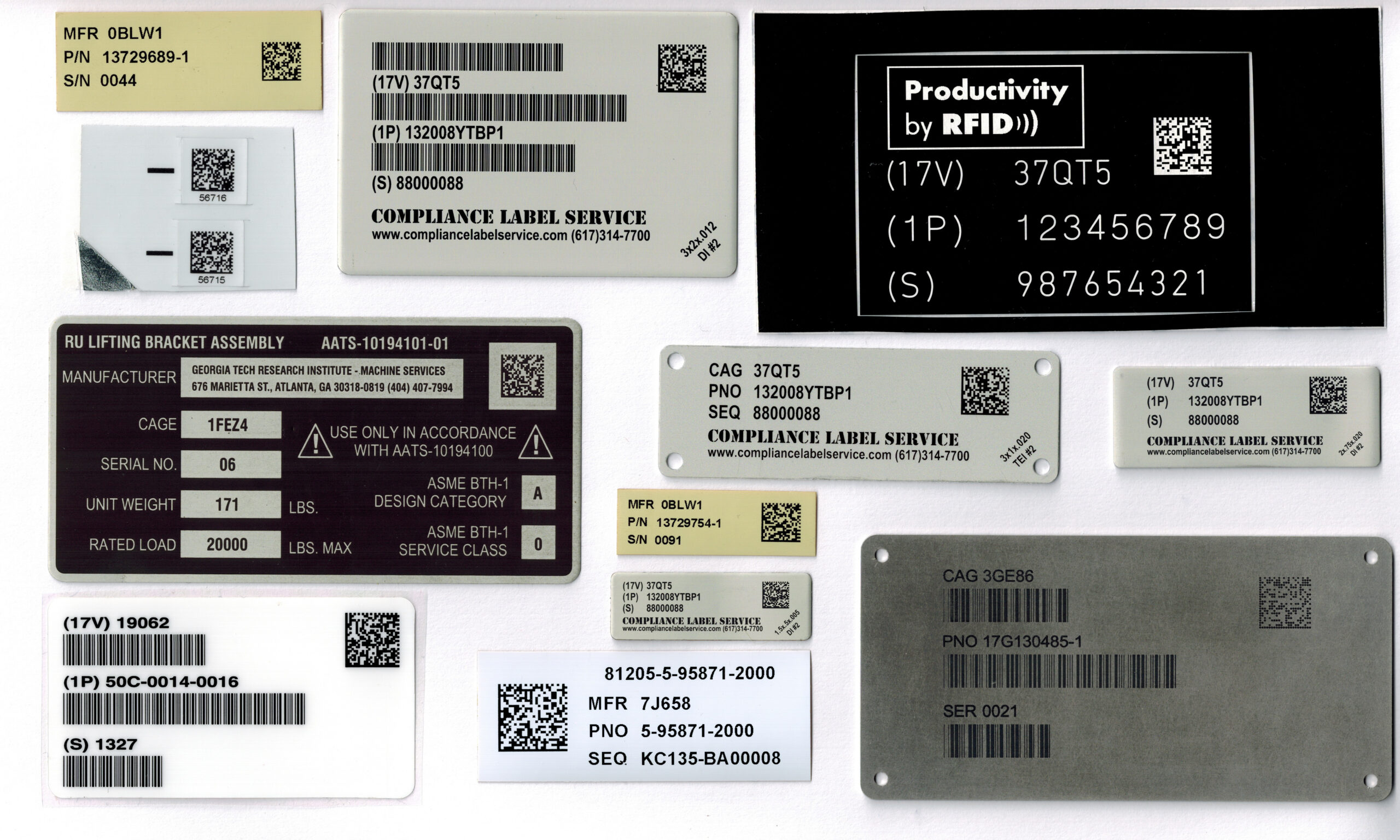

- Do you Serialize within the Part Number? For example: Part Number ZZ45 has Serial Numbers 001, 002, 003, 004. And Part Number WW56 also has Serial Numbers 001,002, 003, 004. This is serializing within the Part Number. We will guide you to Construct 2 for your 2D Data Matrix barcode and it will encode your CAGE, Part Numbers and Serial Number. If space is available, we will inform you that MIL-STD-130 prefers the Human Readable Information to also include CAGE, Part Number and Serial Number.

- Or do you Serialize within your company:? For example: Serial Number ZZ45001 is made at 7:00 am and the next part, made at 8:30 am, is ZZ45002. No other part of any type shares these Serial Numbers. This is serializing within the company. We will guide you to Construct 1 and your 2D Data Matrix barcode will include CAGE and Serial Number. If space is available, we will inform you that MIL-STD-130 prefers the Human Readable Information to include CAGE and Serial Number.

- If you don’t have a Serialization scheme, we’ll help create one!

B. We guide you to the best ENCODING FORMAT for you

An Encoding Format tells a barcode reader the type of data it’s about to read: CAGE, Part Number or Serial Number. There are 3 options:

- Data Identifier (DI) – – Format 06 ISO/IEC 15434. We find this format the most widely used and understood and therefore recommend it.

- Text Element Identifier (TEI) – Specified in ATA Spec 2000, TEI is also called Format 12.This is the next most widely used format.

- Application Identifier (AI) –Format 05 ISO/IEC 15434. This format is very rarely used and we do not recommend it.

C. We guide you to select the right DATA and evaluate it for compliance with MIL-STD-130

We’ll guide you when to use your CAGE, or your supplier’s, or your Prime’s; Or, whether to use your Part Number or DoD’s NSN; Or, whether to use your SERIAL Number or your supplier’s.

We’ll also check your data against the limited character set allowed by MIL-STD-130. It accepts only upper case letters A thru Z, numbers 0 thru 9, and special characters forward slash / and dash -. It does not accept periods, spaces, or any other special characters!

D. We check your contract or SOW to see if other data is required

Although most DoD contracts don’t, some contracts or SOWs do require additional data. This may include Company name, DoD contract, linear barcodes, Lot number, Date of Manufacture, Voltage, Power, Warranty dates, etc.