FREQUENTLY ASKED QUESTIONS: MIL-STD-129

What are the basic label types required by MIL-STD-129?

MIL-STD-129 requires Military Shipping Labels, Exterior Container Labels, Unit Container Labels, and Intermediate Container Labels.

Unit Container labels. bear data in human-readable format and in a PDF417 2D data matrix barcode, specified by MIL-STD-129. Included data are NSN, CAGE, Part Number, Item Description, Quantity, Unit of Issue, Contract number, Preservation Method and Date of Preservation. If required, serial numbers, lot numbers, and shelf life dates are also included. Intermediate Container labels bear the same information.

Unit Container labels. bear data in human-readable format and in a PDF417 2D data matrix barcode, specified by MIL-STD-129. Included data are NSN, CAGE, Part Number, Item Description, Quantity, Unit of Issue, Contract number, Preservation Method and Date of Preservation. If required, serial numbers, lot numbers, and shelf life dates are also included. Intermediate Container labels bear the same information.

Exterior Container Labels include contract and content data and PDF417 2D data matrix barcode specified by MIL-STD-129.

Military Shipping labels include ‘Ship From’ and ‘Ship To’ address data, several Code 39 linear barcodes and a large PDF417 2D barcode.

For more information, please visit MIL-STD-129 Label Types

Where on the shipping containers should MIL-STD-129 labels be placed?

Please see WHERE TO STICK’EM.

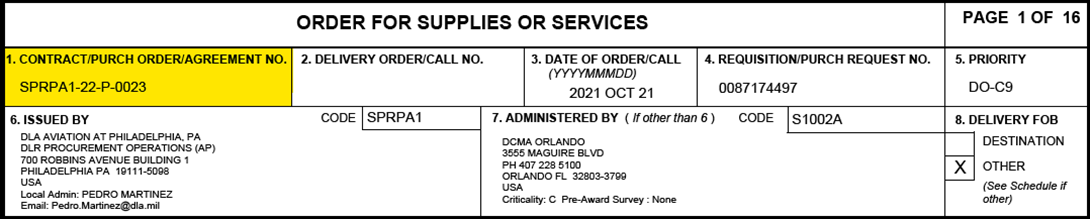

What is a Procurement Instrument Identifier (PIID)?

The Department of Defense uses many terms for an acquisition instrument: Contract, Purchase Order, Delivery Order, Call, or Solicitation Number. Now, there’s a new standardized identifier to replace them all…Procurement Instrument Identifier (PIID).

The Department of Defense uses many terms for an acquisition instrument: Contract, Purchase Order, Delivery Order, Call, or Solicitation Number. Now, there’s a new standardized identifier to replace them all…Procurement Instrument Identifier (PIID).

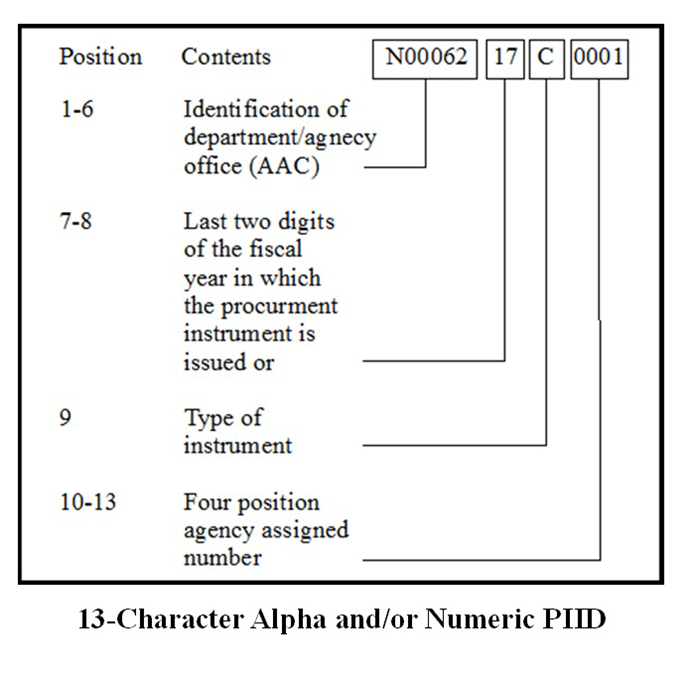

Each PIID is unique and consists of 13-to-17 alpha and/or numeric characters sequenced to convey certain information, as indicated by the adjacent illustration from FAR 4.1603.

Where can I find my contract’s PIID?

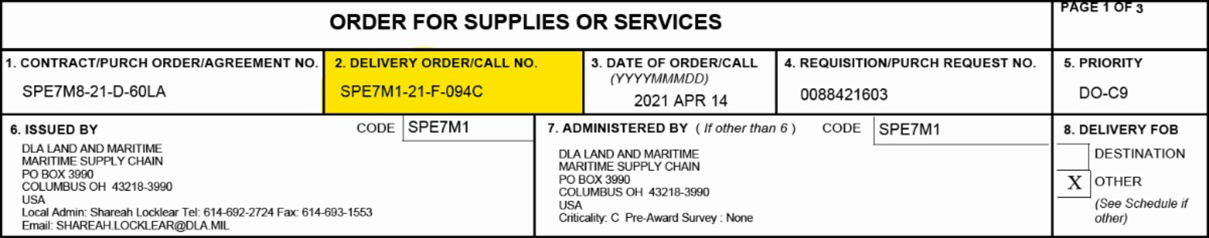

First, refer to your ORDER FOR SUPPLIES OR SERVICES.

Next, find BOX 2: DELIVERY ORDER/CALL NO. If populated, that number is your PIID.

If Box 2 is empty, use the number in BOX 1: CONTRACT/PURCH ORDER/AGREEMENT NO.

If your contract has been modified, add the 6-character AMENDMENT/MODIFICATION NO to the end of the 13-character PIID.

Example: SPRPA1-22-P-0023-P00002

For legacy contracts, use the number in BOX 1 as the PIID, then add the 4-character DELIVERY ORDER NO to the end.

How do I figure out the CUBE of my pallet or shipping container?

![]() EXPEDITER™ has a handy calculator, located to the right of the “Cubic Foot” input field, that will automatically calculate the CUBE when the container dimensions (in inches) are entered.

EXPEDITER™ has a handy calculator, located to the right of the “Cubic Foot” input field, that will automatically calculate the CUBE when the container dimensions (in inches) are entered.

If you would like to manually calculate the CUBE, simply multiply the length, width, and height (in inches) and then divide by 1,728. Always round up to the next whole number. Ex. (48” x 40” x 36”) / 1728 = 40 CUBE

What happens if my Individual Shipping Container is 10 CUBE or over?

If your Individual Shipping Container is 10 CUBE or over, MIL-STD-129 requires that a second ECL is placed on the end of the container to the left of the identification-marked side. (see MIL-STD129R w/CHANGE 2, page 40, 5.3.2.1)

If your Individual Shipping Container is 10 CUBE or over, MIL-STD-129 requires that a second ECL is placed on the end of the container to the left of the identification-marked side. (see MIL-STD129R w/CHANGE 2, page 40, 5.3.2.1)

EXPEDITER™ will automatically generate this extra label for you, when your shipment has a CUBE of 10 or over.

How do I create a Transportation Control Number (TCN)?

If your contract includes a Transportation Control Number (TCN) or a MILSTRIP Number, it must be included on the MSL(s). If you were not provided with a TCN, then it is not mandatory to include one but you can create your own.

![]() EXPEDITER™ offers a TCN Wizard , located to the right of the TCN input field, to help you create one. Click the red icon of a truck located to the right of the TCN input field.

EXPEDITER™ offers a TCN Wizard , located to the right of the TCN input field, to help you create one. Click the red icon of a truck located to the right of the TCN input field.

- Enter the date you are creating the TCN—MM/DD/YY

- If this is the first TCN number that you are creating today (ex. 001 for 1st TCN, 002 for 2nd, 003 for 3rd, etc.)

- Click ‘Save’ and EXPEDITERTM will have assigned and entered your 17-character TCN number for you!

What if I don’t know the exact Ship Date?

The DoD allows an approximate 7-day leeway between the actual Ship Date and the Ship Date printed on the MSL. If you are not completely confident in the exact date your supplies will ship but know the week, you can still place your order using an estimated date within that week.

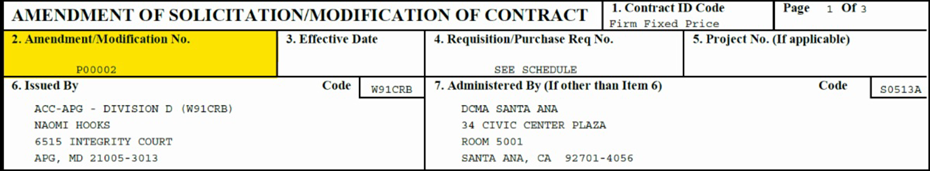

What is a Shipment Number?

Contract holders are required to assign a SHIPMENT NUMBER to each and every shipment. Each shipment to each DODACC/SHIP TO location must be assigned a SHIPMENT NUMBER that is different from one another and unique to that PIID. Shipment numbers consist of seven characters with the final shipment number consisting of an eighth character ‘Z’ .

Contract holders are required to assign a SHIPMENT NUMBER to each and every shipment. Each shipment to each DODACC/SHIP TO location must be assigned a SHIPMENT NUMBER that is different from one another and unique to that PIID. Shipment numbers consist of seven characters with the final shipment number consisting of an eighth character ‘Z’ .

- The first 3 characters are letters and can be different for each “Shipped From” location. They remain constant throughout the contract.

- The last 3 characters are numbers

- The 4th character can be either a letter or number

- The final shipment of the contract adds ‘Z’ as an 8th character to indicate there are no additional shipments for this contract

What is the difference between a Palletized Load and an Individual Shipping Container?

A Palletized Load is a pallet on which there are two or more containers. A pallet with one container or one item atop is considered an Individual Shipping Container, not a Palletized Load. Individual Shipping Containers can be boxes, cases, bundles, assemblies, barrels, drums, etc. A Gaylord Box on a pallet is considered an Individual Shipping Container

A Palletized Load is a pallet on which there are two or more containers. A pallet with one container or one item atop is considered an Individual Shipping Container, not a Palletized Load. Individual Shipping Containers can be boxes, cases, bundles, assemblies, barrels, drums, etc. A Gaylord Box on a pallet is considered an Individual Shipping Container

If a contract holder selects a partner (with a different CAGE) to manufacture and ship the product, which CAGE and SHIP FROM should be used on the Military Shipping Label (MSL) in the “From” box?

The SHIP FROM address should be that of the manufacturer where the shipment originates. The CAGE should be that of the contract holder.

FREQUENTLY ASKED QUESTIONS: RFID

What is RFID?

RFID stands for Radio Frequency Identification which is an automatic identification technology in which data is transferred wirelessly via radio waves between RFID readers and transponders (RFID tags or RFID labels). Data transfer by RFID is performed in milliseconds, without human involvement (i.e. hands free), and without a line-of-sight which is required to read bar codes. RFID tags can signal their presence, unique identity, location, and other user defined information.

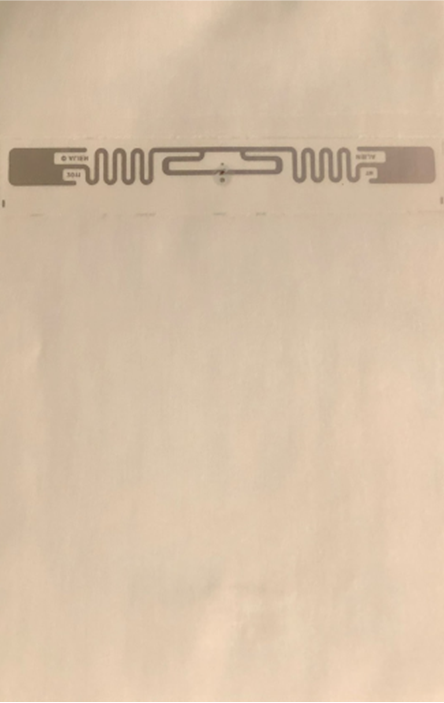

What are MIL-STD-129 Labels with RFID?

MIL-STD-129 labels with RFID are passive tags which have no internal power source. The DoD supply chain uses RFID because it provides benefits in inventory management, asset visibility, and interoperability. For tracking cases and pallets in the supply chain, DoD mandates the use of 96 bit, passive RFID tags which conform to the EPC UHF Class 1 Gen 2 standard.

MIL-STD-129 labels with RFID are passive tags which have no internal power source. The DoD supply chain uses RFID because it provides benefits in inventory management, asset visibility, and interoperability. For tracking cases and pallets in the supply chain, DoD mandates the use of 96 bit, passive RFID tags which conform to the EPC UHF Class 1 Gen 2 standard.

This figure shows the back of a blank 4” x 6” label which is embedded with a RFID chip and antenna.

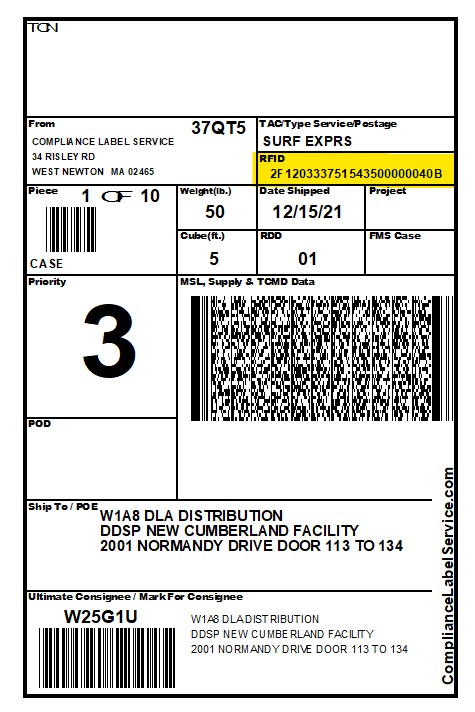

What is an RFID number?

The DoD specifies that RFID numbers are displayed in hexadecimal format, which appears as 24-alphanumeric characters. The required data within an RFID number consists of a Header, Filter, Government Managed Identifier (or CAGE code) and Serial Number. The “serial number” portion of the complete RFID number, does not refer to the serial number of the product being shipped. Rather, this “serial number” or “ID number” is a unique number assigned to a specific case or pallet. It is never acceptable to repeat an RFID number across two or more passive RFID tags.

RFID Number Example: 2F120333751543500000040B

How do I know if my contract might require MIL-STD-129 labels with RFID?

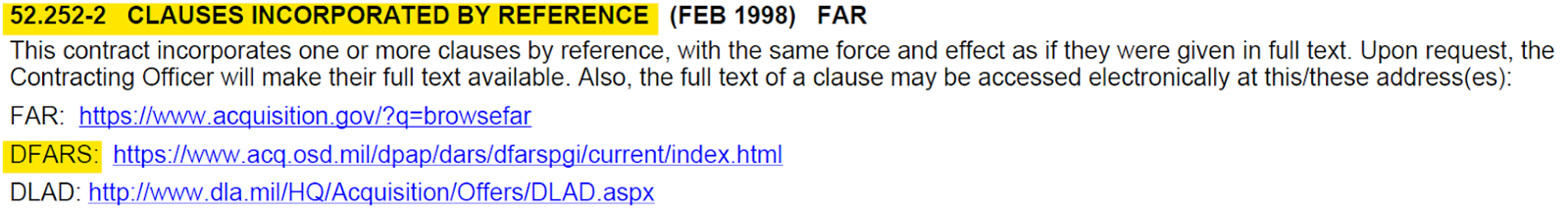

RFID MAY BE REQUIRED IF your contract includes 52.252-2 CLAUSES INCORPORATED BY REFERENCE with DFARS listed

OR specifically calls out DFARS 252.211-7006 PASSIVE RADIO FREQUENCY IDENTIFICATION.

If your contract DOES include –

- 52.252-2 CLAUSES INCORPORATED BY REFERENCE with DFARS listed, and/or

- DFARS 252.211-7006 PASSIVE RADIO FREQUENCY IDENTIFICATION

– AND the commodity shipped belongs to one of the Classes of Supply below, you might need RFID.

- Subclass of Class I – Packaged operational rations.

- Class II – Clothing, individual equipment, tentage, organizational tool kits, hand tools, and administrative andhousekeeping supplies and equipment.

- Class IIIP – Packaged petroleum, lubricants, oils, preservatives, chemicals, and additives.

- Class IV – Construction and barrier materials.

- Class VI – Personal demand items (non-military sales items).

- Subclass of Class VIII – Medical materials (excluding pharmaceuticals, biologicals, and reagents – suppliers should limit the mixing of excluded and non-excluded materials).

- Class IX – Repair parts and components including kits, assemblies and subassemblies, reparable and consumable items required for maintenance support of all equipment, excluding medical-peculiar repair parts.

RFID is NOT REQUIRED for shipments of –

- Bulk commodities, or

- When shipping to locations other than Defense Distribution Depots when the contract includes the clause at FAR 52.213.-1 Fast Payment Procedure.

In summary, RFID IS REQUIRED if your contract –

- INCLUDES 52.252-2 CLAUSES INCORPORATED BY REFERENCE with DFARS listed, and/or specifically lists DFARS 252.211-7006 PASSIVE RADIO FREQUENCY IDENTIFICATION

- AND the commodity shipped DOES BELONG to one of the listed Classes of Supply

- AND IF the shipping address is listed at clause at (b)(1)(ii) https://www.acq.osd.mil/log/sci/RFID_ship-tolocations.html (However, the Acquisition & Sustainment Office of the Under Secretary of Defense no longer has this page active, leaving suppliers unclear as to the RFID requirement. Updated November 22, 2022.)

- OR IF the shipping address is a location outside the contiguous US (OCONUS) with an assigned Transportation Priority 1

- OR IF the shipping address is specifically listed in (b)(1)(ii)(B) as having been deemed necessary by the requiring activity

Still unclear? The Subject Matter Experts at Compliance Label Service are always glad to talk about RFID.

If RFID is required, which containers of my shipment must have them?

When RFID tags are required, per MIL-STD-129 and DFARS 252.211-7006, they must be applied at the case (exterior container or shipping container) and pallet (palletized unit load) levels.

Therefore, if you are shipping Individual Shipping Containers (cases, boxes, crates, reels, etc.), an RFID tag must be placed on every outermost box of the shipment. The RFID tag is typically embedded in the Military Shipping Label (MSL).

If you are shipping a Palletized Load (2 or more containers on a pallet), then both the MSL and the ECLs are embedded with RFID tags.

The DoD also requires the RFID numbers of each case and pallet bearing RFID labels to be sent in an Advanced Shipment Notice (ASN) to WAWF. This appends the RFID numbers to the WAWF Receiving Report of the associated DoD contract. It can be done via manual data entry or electronically.

Where can I find my assigned RFID Number(s)?

Compliance Label Service makes it easy to find your assigned RFID number(s). Simply look in one of these places for the 24-character hexadecimal number:

-

- On the MSL (Military Shipping Label) look at the top right corner for a box titled ‘RFID’. The unique RFID number is marked on each label here.

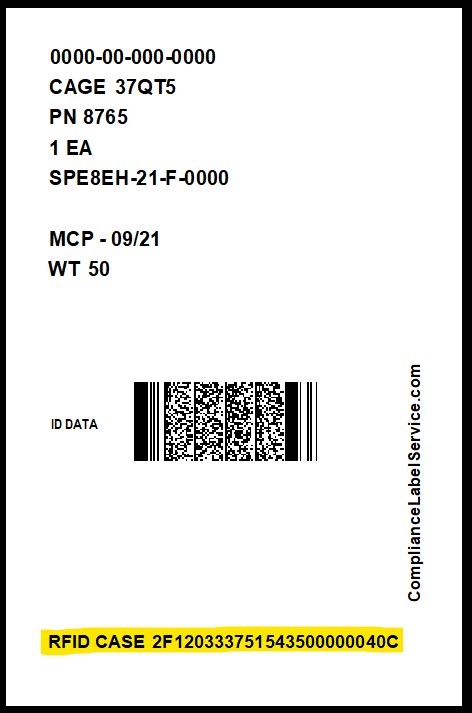

- If your shipment is a Palletized Load, then your ECLs (Exterior Container Labels) may also have RFID. The unique RFID number is listed on the bottom of the ECL.

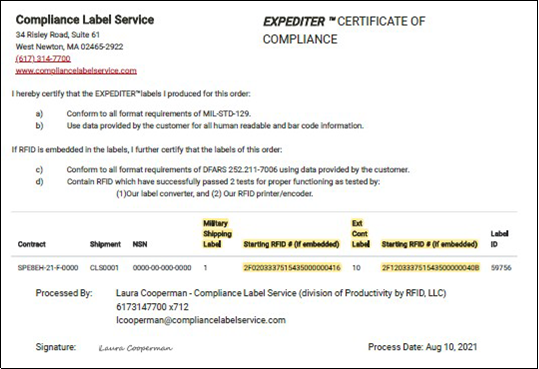

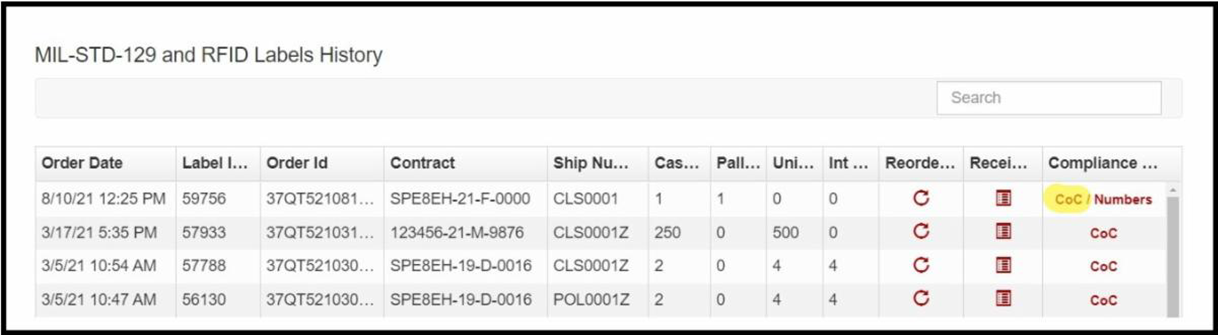

- The COC (Certificate of Compliance) for each order lists the Starting RFID# for the first MSL(s) and, if applicable, the starting RFID# for the ECL(s) of every label ID in that order.

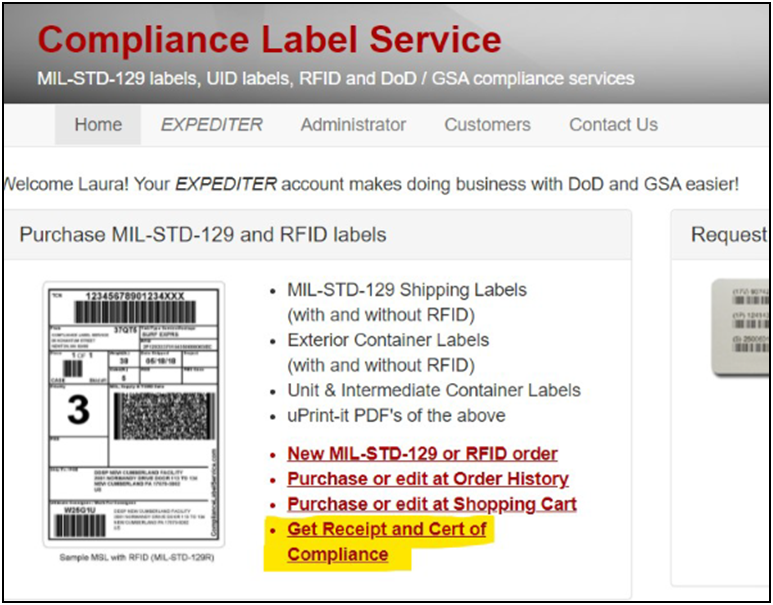

- If you cannot find the hardcopy of your Receipt/COC shipped to you with your order, you can always access a PDF in your EXPEDITER™ account. Under ‘Purchase MIL-STD-129 and RFID labels’ simply click on ‘Get Receipt and Cert of Compliance’ and then the COC link.

- On the MSL (Military Shipping Label) look at the top right corner for a box titled ‘RFID’. The unique RFID number is marked on each label here.

How do I get a .CSV file of my RFID numbers to easily add to WAWF?

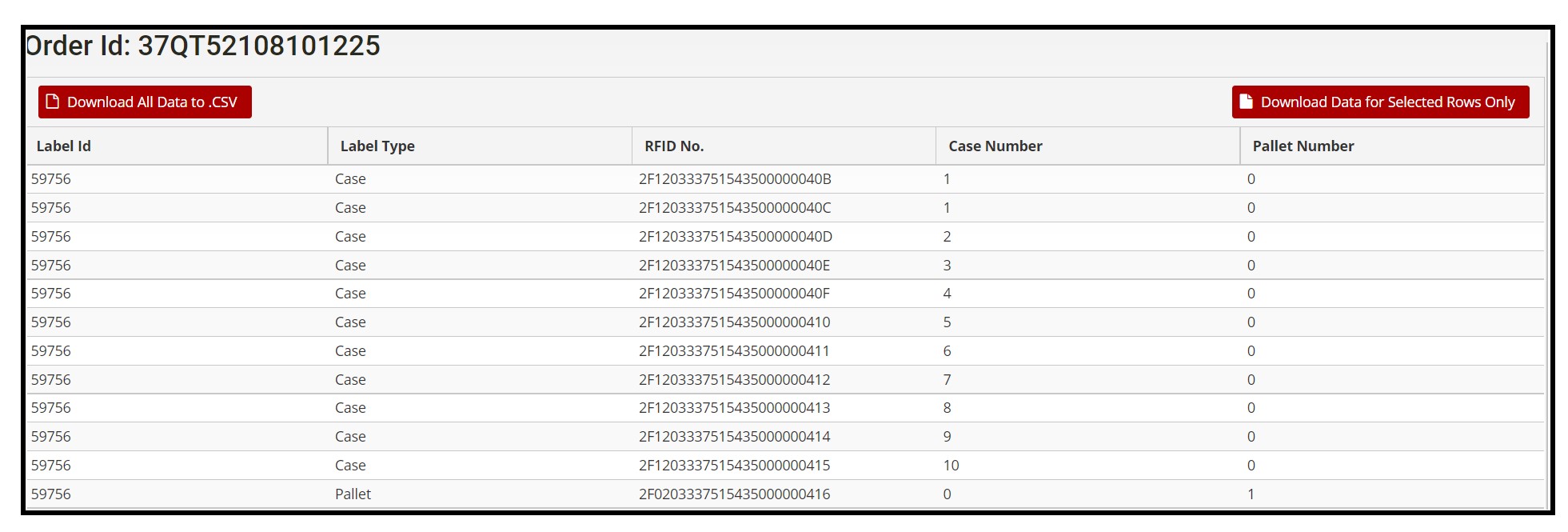

Compliance Label Service has made it easy to add multiple RFID numbers into WAWF by providing customers access to a .CSV file of your RFID numbers. Instead of typing each RFID number individually, you have the ability to cut and paste from the .CSV file directly into WAWF. Access this feature by selecting the ‘Numbers’ link.

There are two options for downloading the RFID data. Option 1 is to ‘Download All Data to .CSV’ and Option 2 is to ‘Download Data for Selected Rows (Label IDs) Only’.